When it comes to printing, the possibilities have evolved tremendously, beyond banners, posters, and t-shirts, now it is possible to print on almost anything. It’s become easier to print on glass, wood, ceramic tiles, and even on metal. The continuous technological advancements in the field of printing and the growing need for customization and personalization bring something new and something that can be a game-changer for businesses and industries. This rings a bell to a printing innovation called digital UV printing.

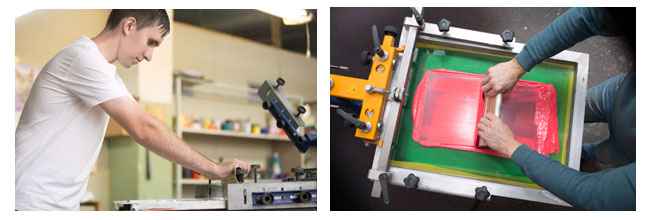

What is screen printing?

Screen printing is an age-old printing technology used since the 1900s. Screen printing first appeared in a recognizable form in China. It was then adapted by other Asian countries like Japan and was further created using newer methods. Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. Designs made using the screen printing technique may use just one shade of pink, or several. In the case of multicolored items, the colors must be applied in individual layers, using separate stencils for each ink.

What is UV Printing?

With built-in UV light, the ink dries up instantly and does not lead to smearing or blotching. This helps the UV printers print on almost all media, which makes them truly versatile which includes varieties of rigid materials include as glass, tiles, wood, ACP, acrylic, etc., and also flexible media such as wallpapers, canvas, and much more. It can print stunning colors and incredible textures directly onto almost anything. In addition to vibrant colors and extraordinary details, they can also produce stunning photographic details.

What’s best for you?

“Necessity is the mother of invention” is a well-known proverb. It means, that the primary driving force for most new inventions is a need. When the need for higher productivity, customization, and ease of printing becomes the need of modern age printing, that led to the evolution of the new age UV printing.

A face-off between modern and traditional printing technologies will give a clear idea as to which technology can give you better results. Here are a few parameters worth considering:

- Cost and productivity

Screen printing involves a wide range of stencils to be created, so they are not suitable for lower quantities. However, if bulk order is to be printed the same stencils can be used, hence screen printing may be viable. UV printing is far quicker than conventional printing. You no longer need to wait for the ink on your pieces to dry, as the UV ink dries through a photomechanical process. It’s almost instantaneous, so you can get more in less time and clearly saves more money through faster drying times.

- Versatility

Screen printing is a robust technology but majorly concentrated on apparel and t-shirts. The digital UV printing can be extended to almost any kind of surface like acrylic, aluminum, glass, metal, and wood. UV Printers offer customization of objects such as mobile phone cases, glass, wooden items, ceramic tiles, product display items, décor pieces, instruments, artwork and many more specialty items that command high prices. UV-LED printers are highly versatile and perfect for clients who want to tap multiple markets. A wide range of printing has been possible due to the versatility of the UV Printers.

- Use of Inks

The UV printing uses ink that contains a chemical called photoinitiators which trigger a chain of reaction on being contacted by UV light. This ink dries up instantly with UV light. The screen printing uses three types of ink-plastisol, water-based inks, and discharges inks. Each ink has limitations with regard to the drying up the process and the after-wash quality.

- Environment-Conscious

With an increasingly aware generation, this factor is gaining importance gradually. Plastisol used in screen printing contains PVC, which is a harmful pollutant. Water-based inks are relatively more eco-friendly. However, UV printing is very environment-friendly which neither uses heat nor toxins in the process; hence is a clear winner of this category.

The final verdict

Depending on the product and the quantum of production, the decision to choose the technology of printing may vary. However, UV technology enables printers to become more versatile, compact, and environmentally friendly. This will surely help you to increase the customer base, retain the existing clients and offer better quality for lower cost of production.

Maximize your portfolio with Pixeljet® digital UV printers

Expand your reach and add more value to your business. The UV technology used in the Pixeljet® UV printers is capable of printing on almost any media. It can print on glass, wood, PVC, ACP, Ceramic tiles, acrylic, decorative applications, and many more. Pixeljet® UV printers have opened up a whole new dimension of opportunities and revenue options.