Monotech Systems launches Pixeljet® miniRTR

(New Pixeljet® miniRTR with RICOH print heads)

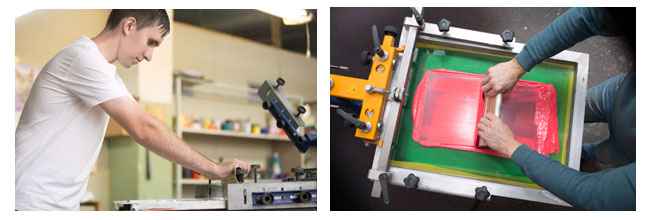

Focusing on future technologies, innovation and step towards green printing, Monotech Systems has launched a new version of their existing 6 feet UV LED roll-to-roll printer named Pixeljet® miniRTR The advanced version of miniRTR is capable of printing high quality indoor and outdoor signage along with various interior décor applications.

“This new launch is an updated version of our existing model Pixeljet® miniRTR. The new advanced version of miniRTR is now available with the RICOH industrial grade print heads which is the most popular head when it comes to the UV printing technology.” Says, Manoj Garg, General Manager – Wide Format Graphics, Monotech Systems Limited.

“The RICOH industrial grade printhead offers enhanced productivity that enables the miniRTR to deliver a printing speed of up to 150 sq. ft. /hr. (based on the printhead and color configurations). It also brings the media versatility and enable the printing on wide range of indoor, and outdoor applications such as transparent materials, self-adhesive vinyl, outdoor materials, films, leather, and also on décor applications such as wallpapers, window blinds, wall decals, canvas etc.” Mr. Garg added.

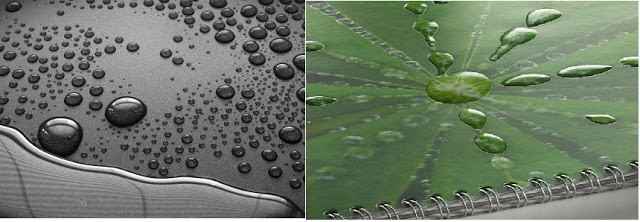

The New Pixeljet® miniRTR UV LED roll-to-roll printers available in six- and four-color versions. The Pixeljet® miniRTR is equipped with a UV LED lamp, allowing users to print on a variety of media and save energy, cost and time.

One of the main features of this printer is its four-color optional varnish plus white and clear ink version, which can print white in different modes, improving the opacity of printed materials, increasing color contrast and readability. It also delivers embossing effects for various digital decorations. The new Pixeljet® miniRTR is designed for mid-range users who want to switch from Eco-Solvent to UV printing on a budget.

Key Specifications of the New Pixeljet® miniRTR:

- Maximum Printing Size: 1800 mm

- Resolution: 2,400 dpi

- Printing speed: Up to 150 sq. meter/hour

- Printhead: RICOH industrial grade print head

- Color options: (CMYK) + White + Clear ink